Contributed by Scott Stamper , Environmental Specialist, PPM Consultants

, Environmental Specialist, PPM Consultants

Have you ever wondered exactly how the fuel gets to that dispenser when you pull up to the service station and fill up? The average citizen, I assure you, has not given this much thought. We swipe our credit card, select what fuel grade we like, place the nozzle in our vehicle and fill up. However, it is much more complicated than that. Most service stations store their fuel in an Underground Storage Tank (UST) system which consists of not only the UST’s, but also the product piping which carries the fuel from the tank to the dispenser, and the dispenser itself. Each part of this UST system plays a vital role to ensure you get your fuel quickly and most importantly, safely.

Of course, to ensure you get the fuel quickly and safely, the UST system must be regularly checked to ensure nothing is leaking or malfunctioning. In 2015 EPA promulgated new rules one of which was requiring monthly walk through inspections.

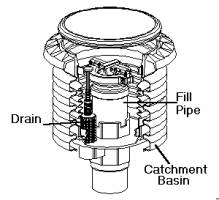

A 30-day walk through inspection has three main components: 1) checking the leak detection system of the UST; 2) inspecting the condition of the spill catchment basin (spill bucket) to see if there are liquids present that must be removed (whether product or water); and 3) making sure the integrity of the spill bucket structure is intact and capable to hold small incidental spillage during loading of the tank.

A 30-day walk through inspection has three main components: 1) checking the leak detection system of the UST; 2) inspecting the condition of the spill catchment basin (spill bucket) to see if there are liquids present that must be removed (whether product or water); and 3) making sure the integrity of the spill bucket structure is intact and capable to hold small incidental spillage during loading of the tank.

First, we will start with the leak detection at the UST. The USTs store the fuel until it’s delivered to the dispenser and into your vehicle. The UST typically has an automatic tank gauge (ATG) probe which monitors not only the fuel level, but also the water level inside the tank. This ATG probe plays a vital role in detecting a leak. The ATG sends statistical data to the ATG console (commonly a Veeder Root or OPW) which triggers an alarm inside the store to warns of a potential problem. These statistical leak reports can be run on demand but are generally programmed to run and print at least once per month. This monthly report is part of the 30-day walk-through inspections. Most single-wall UST systems have these ATGs to satisfy their leak detection requirements. However, another form of leak detection is called SIR (Statistical Inventory Reconciliation) which requires daily tank measurements to see exactly how much fuel (in inches) is in your UST. Then, you look at a tank chart, specifically for that tank, which shows you exactly how many gallons of fuel are in that tank at that precise fuel level in inches. Now that you have your amount of fuel in gallons in that tank, you have to subtract the amount of fuel (in gallons) sold the previous day and/or add the amount of fuel (in gallons) delivered. This form of leak detection may sound obsolete, but it is very effective at discovering a leak over each 30 day period. For double-wall tanks, if they were installed after August of 2007, they must use interstitial monitoring for leak detection. There is a space between the inner and outer shell of a double wall tank called the interstice. The interstice has a sensor which detects the presence of liquid and triggers an alarm at the ATG console. To fulfill the leak detection requirement and the 30-day walkthrough inspection requirements, a liquid status report must be run (and printed) every 30 days and should be included as part of the inspection report.

The next consideration is simply evaluating the condition and contents of the spill bucket. If the spill bucket contains water or fuel, it must be removed and disposed so that it’s full containment volume is available in the event of incidental spillage during loading of the UST. The condition of the spill bucket must be inspected for damage, if they are double-walled the interstice must be checked for liquid, the fill pipe should be inspected for damage, and the cap should fit securely on the fill pipe.

There are subtle variations in each state but these are the basic requirements of a 30-day walkthrough. While some are outsourcing this work, it can be very easily conducted by facility personnel to avoid significant cost to the facility. For example, if an outsourced entity charges $80 per month to conduct the inspection that is $960 per facility. This can add up for those owners with multiple facilities.

If you have any questions regarding 30-day walk through inspections, please feel free to reach out to me at scott.stamper@ppmco.com. Be on the lookout for discussions on Annual Walkthroughs and annual/3-yr testing requirements in upcoming articles.